Chips, Man: From Sand to Your Smartwatch!

Ever wonder what secret sauce powers all your gadgets? Like that shiny phone, your laptop humming away, or even that ancient gaming console you won’t throw out – it’s all down to these tiny miracles. We’re talking about microchip manufacturing, a crazy intricate setup that feels like something out of a sci-fi flick. How do these minuscule, powerful chips actually get built, anyway? It’s a journey from simple beginnings to totally mind-blowing nanometer tech. Seriously complex stuff.

So, Chips Are Made of Sand. Yeah, Sand!

The whole thing kicks off not with some rare metal, but just plain old sand. But not just any sand. Nope. We’re talking super pure quartz stuff, pulled from places like North Carolina right here in the U.S., or sometimes from Russia, China, Norway, and Brazil around the globe. This isn’t your everyday beach sand; it’s practically all silicon, with very little iron.

This raw sand then goes through a hardcore chemical wash, stripping out dirt until it’s a jaw-dropping 99.999% pure. Wild, right? This spotlessly clean sand gets melted down with special gear. Then, it turns into these big, round ingots of silicon.

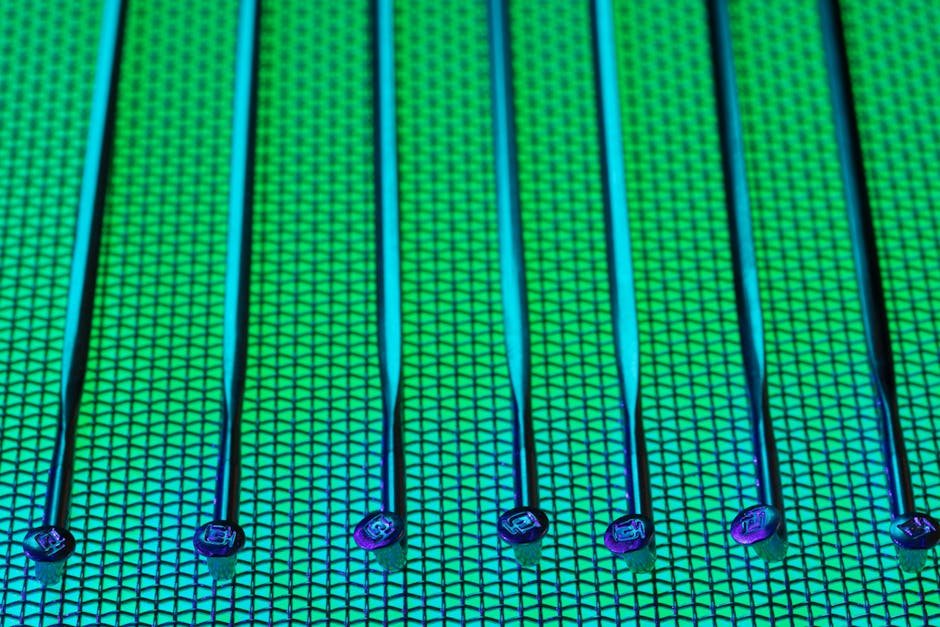

But these silicon cylinders aren’t ready for prime time. Not yet. They’re meticulously sliced into super thin discs using diamond blades. Think high-tech deli slicer. These delicate discs, called wafers (or sometimes just ‘plates’), then get their surfaces polished. An extreme, mirror-like smoothness. Just preps ’em for the next, super important steps.

Building Chips: Light, Ions, and Layers – A Crazy Dance

Once those wafers are prepped, the real fun starts with photolithography. Each wafer gets slathered with special chemical layers. Then, a fancy masking system swings into action: powerful ultraviolet light. It acts like a microscopic pen, drawing intricate patterns and grooves right onto the wafer. These patterns map out the tiny circuits to come.

After the light art, selected chemical baths wash away unwanted areas. Leaving behind only those precise patterns. Next, the wafers get hammered with ions. This process, ‘ion implantation,’ cleverly tweaks the silicon’s electrical properties. It guides the electricity flow, and – boom! – the very first transistors begin to form.

Layer upon layer, the intricate dance continues. Conductive metal bits are placed onto the wafer. Building up the complex pathways that make the chips’ circuits. After endless cycles of etching, building up, and cleaning, dozens—sometimes hundreds—of individual microchips form on one single wafer. Each one, a potential brain or memory for your tech.

But before these chips are cut from the wafer, they’re tested. Really tested, by special machines. Because even with the latest tech, not every chip comes out perfect. Some hit peak potential. Others? Minor flaws. And some are just duds. They are categorized for different product tiers. Which is how you get your high-end Ryzen 9s and the more chilled-out Ryzen 5s.

Finally, diamond blades precision-cut each chip from the wafer. But they’re still not usable. They need packaging. And this isn’t just a box. It’s a protective assembly that adds a thermal shield, a metal casing, a circuit board for connections, and pins to hook into motherboards and suck down power. And another thing: after packaging, you guessed it, more testing! This final gauntlet decides their ultimate market fate.

The Big Guns in Chip Making: Taiwan, South Korea, U.S., Japan

When we talk about the big-time players in chip development and actually making them, it’s a global race. A lot of countries come up with their own microchip designs – the U.S., Germany, Netherlands, China, Japan, South Korea, and Taiwan all have companies pushing boundaries. But actually producing these chips in huge numbers? That’s a completely different league.

American giants like Nvidia, AMD, and Apple design some of the most advanced silicon you can imagine. But for big-time, cutting-edge production, they usually rely on partners overseas. Taiwan is the clear leader here, no argument. TSMC controls roughly 65% of the high-tech microchip market. Getting a spot on their production lines? That’s a super competitive, high-stakes game.

Not far behind is South Korea’s Samsung. Japan, meanwhile, is a major force in making microchips. Especially for cars. Intel, a U.S. powerhouse, stands out because it still makes a lot of its own chips in-house. But for the absolute bleeding edge, South Korea and Taiwan are often the ones Intel calls. China is also moving up mega-fast in making chips for regular electronics, so watch out for them.

And Another Thing: The Dutch Company, ASML, Is Key

You want to make the latest chips by yourself? Good luck without the Dutch. ASML, located in the Netherlands, is probably the most critical company in the whole microchip world. They build these mind-bogglingly complex Extreme Ultraviolet (EUV) lithography machines – those are the ‘light pens’ capable of etching circuits at the smallest scales – and nobody else can beat them right now.

ASML’s tech isn’t just about engineering smarts. It’s a geopolitical linchpin. You can’t just rock up with a briefcase of cash and buy one of their machines. These aren’t consumer goods. Countries like the U.S., Germany, and Japan supply crucial components to ASML. And major sales? They need a political blessing from those countries. This strategic control prevents the tech from going into the “wrong hands.” Read: China, a country working non-stop to create its own version of this stuff.

Nanometer Talk? Mostly Marketing Hype

Alright, let’s get real about those “7 nanometer,” “5 nanometer,” “3 nanometer” bragging rights. Truth bomb: these numbers are largely marketing. Nobody is actually building transistors that are literally 3 nanometers across. It’s a shorthand. A benchmark. An industry flex.

The real game is about boosting efficiency. How do you cram more transistors into the same small space without the whole thing melting down? That means innovating production techniques to make transistors and other parts smaller. But not necessarily to the exact nanometer figure you see in ads. This chip measurement thing really changed after hitting around 32 nanometers.

Today, those nanometer figures might refer to the distance between transistors. Or maybe the width of a transistor’s gate. It’s all super technical, but the core takeaway is this: the advertised nanometer doesn’t equal transistor size. They simply couldn’t get that small even if they wanted to, not without crashing right into the bizarre world of quantum mechanics, where just looking at stuff affects reality. We’re talking superpositions and uncertainty principles here.

The industry is getting close to a fundamental wall, which means talks about moving past silicon to materials like graphene or carbon nanotubes are happening now. What’s next? Nobody knows for sure. But the quest for tinier, faster chips keeps on going.

Turkey’s Chip Game? Military Focus, Not Top Tier

What about other nations, say, Turkey? Can they make microchips? Yeah, they can, but with a big catch. Some Turkish institutions and firms, like ASELSAN, design and build microchips for military applications. Other private companies are also working on it.

But these local producers aren’t hitting the 7nm or 5nm lines that everyone in the global top tier talks about. A few years back, Turkey apparently bought a second-hand 32-nanometer lithography machine. While not the very latest, it’s key to remember this: not every microchip needs to be the absolute smallest. Many modern uses still do just fine with 32nm or even 45nm production lines. Really.

Global Chip Race Is Intense. Always Needing Top Tech

Look, this whole industry is a cutthroat battleground. To grab a piece of the global market, your production tech has to be top-notch. Period. Whether you’re using Samsung’s or TSMC’s 3-nanometer marvels, or hustling like Intel to push your own 1.8-nanometer lines, it’s a non-stop sprint. The pressure to come up with new ways to pack more raw processing power onto a sliver of silicon? Insane. It’s truly a huge feat of human smarts, going from plain old sand to the chips that keep our digital world buzzing.

Quick Questions We Get A lot

What’s a chip mostly made of?

Mostly super clean quartz sand that has lots of silicon. Not just whatever sand you find at the beach.

Do 3nm or 5nm numbers mean the actual size of the transistors?

Nah. These nanometer measurements are mostly marketing lingo. They don’t mean the actual size of tiny transistors. They just show how much better the tech is and how close together they can pack the parts.

Which company is utterly crucial for making those fancy chip machines?

ASML, the company from the Netherlands. Super important. They make the most advanced Extreme Ultraviolet (EUV) lithography machines needed to produce super cutting-edge microchips.